Top Tips for Mastering Drywall Skim Coating

As a contractor with over a decade of experience in drywall installation and finishing, I’ve encountered many challenges on the job site. One particularly challenging project involved an older home with extremely uneven walls and ceilings. Each surface had a different texture, ranging from coarse to completely smooth. The homeowner was desperate for a flawless finish that could add value to the home and make it more visually appealing. My solution? Drywall skim coating.

In this blog post, we will explore effective tips for mastering drywall skim coating, helping you achieve that perfect finish every time. With the right techniques and the high-quality tools available from Level5 Tools, you too can ensure a smooth and professional look in any project.

Understanding Drywall Skim Coating

Before diving into the tips on mastering skim coating, it’s important to clarify what it is. Skim coating is a process where a thin layer of joint compound is applied to drywall in order to create a smooth, even surface. This technique can be used for walls, ceilings, and even for texture removal.

Why Choose Skim Coating?

- Flawless Finish: It provides a fresh, clean look.

- Versatile Application: Ideal for both new drywall and those needing modification.

- Cost-Effective: Can save time and money compared to replacing drywall.

Top Tips for Skim Coating

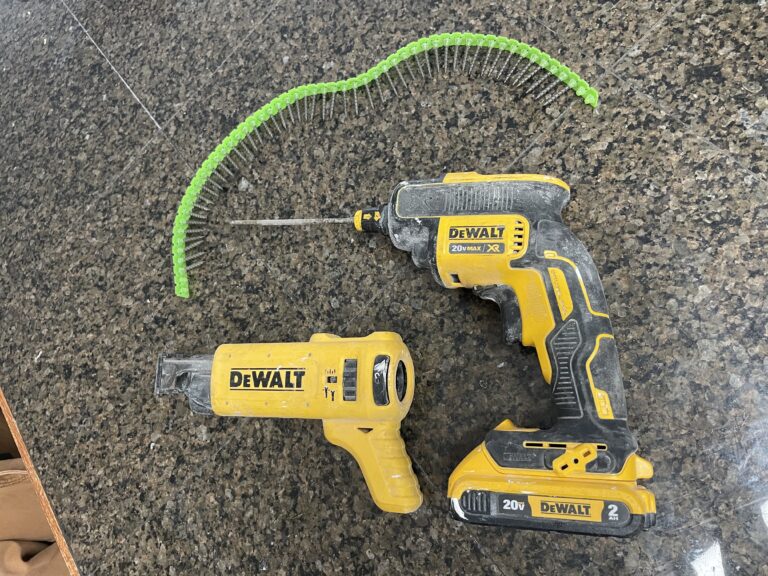

1. Gather the Right Tools

Successful skim coating isn’t just about technique—it’s also about having the right tools. High-quality tools can make all the difference in both the application and the finish’s overall appearance. Invest in essentials from Level5 Tools:

- Skimming Blades: Perfect for achieving a smooth finish. Consider the Level5 Skimming Blades.

- Automatic Taper: Speeds up your application process and improves consistency.

- Taping Knives: Essential for applying compound smoothly.

2. Prepare Your Surface

For effective skim coating, preparation is key. Here’s how to do it properly:

- Clean the Surface: Remove any dust, dirt, or grease. A clean surface ensures better adhesion.

- Repair Imperfections: Fill any large holes or cracks with joint compound and let it dry completely before applying the skim coat.

- Prime If Needed: If the surface is highly porous or has a texture you are trying to hide, a primer can be beneficial.

3. Choose the Right Compound

Selecting the right joint compound is crucial. There are several options, including:

- All-Purpose Compound: Good for most situations but can take longer to dry.

- Setting-Type Compound: Dries quickly and is great for repairs but requires more skill to work with.

- Topping Compound: Best for the final coat due to its smooth finish.

For optimal results, consider using a compound that is recommended for skim coating.

4. Use the Proper Technique

Skim coating is an art, and mastering your technique is crucial for achieving a smooth finish. Here’s how:

- Mix the Compound: Blend it to a smooth consistency, ensuring there are no lumps.

- Apply the First Coat: Use a large taping knife or skimming blade to apply the compound. Start at the top and work your way down in long, smooth strokes.

- Feather Edges: Ensure the edges are feathered out to blend seamlessly with the existing surface.

5. Work in Sections

Avoid overwhelming yourself by working in small sections. This approach ensures that the compound remains workable and allows you to maintain a steady rhythm.

6. Sand Between Coats

After the initial coat has dried, lightly sand the surface with fine-grit sandpaper to ensure a smooth finish. Be sure to wear a mask to avoid inhaling dust.

7. Apply Subsequent Coats

For a truly flawless finish, multiple coats may be required. After sanding the first coat, apply a second coat in the same manner as the first, ensuring a smooth and even application.

8. Use a Corner Finisher for Edges

When working around corners or in tight spaces, using a Corner Finisher can simplify the process and deliver exceptional results. This tool is specifically designed to apply compound to angles, creating a smooth edge without blemishes.

9. Final Sanding

After your last coat has dried, finish by lightly sanding the entire area one more time. Focus especially on the edges and any areas that may have become uneven during the application process.

10. Clean Up Wisely

Proper clean-up can prevent messes in the future. Here are some tips:

- Dispose of Used Materials: Make sure to properly store any leftover compounds and dispose of any waste.

- Wash Your Tools: Clean your tools immediately after use to prevent compound from hardening and ruining them.

Additional Resources for Drywall Finishing

If you want to delve deeper into drywall techniques, consider checking out our articles on The Best Drywall Taping Techniques and Drywall Skimming Tips for a Flawless Finish.

Each additional resource can enhance your skills, ensuring that your work stands out in quality and finish.

Conclusion & Call to Action

In summary, mastering drywall skim coating involves gathering the right tools, preparing surfaces meticulously, and applying compounds skillfully. With practice and patience, you can achieve professional-quality results.

Are you ready to elevate your drywall finishing skills? Whether you’re a seasoned contractor or a DIY enthusiast, honing your skim coating technique can save you time and produce impressive results. For top-notch tools that elevate your work, visit Level5 Tools today!

What challenges have you faced while skim coating? Share your experiences in the comments, and let’s discover solutions together!